Springdale Green, a 30-acre brownfield and former petrochemical tank farm in East Austin, is currently being reclaimed and transformed into a sustainable office campus. With much of the site located within the floodplain of an urban creek, the campus’ architecture is concentrated in one corner, allowing a large portion of the landscape to be dedicated to environmental rehabilitation. One of the central landscape elements through this space is the boardwalk, a universally accessible 1km loop that links the campus core to the landscape beyond. The boardwalk weaves through restored meadow, woodland, and riparian habitats, and allows the floodplain—often seen as a hazard or burden to developments—to become a celebrated amenity.

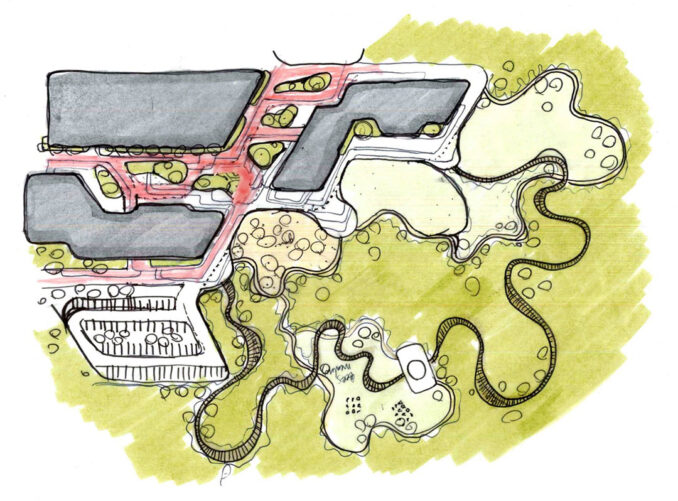

Initial concept sketch

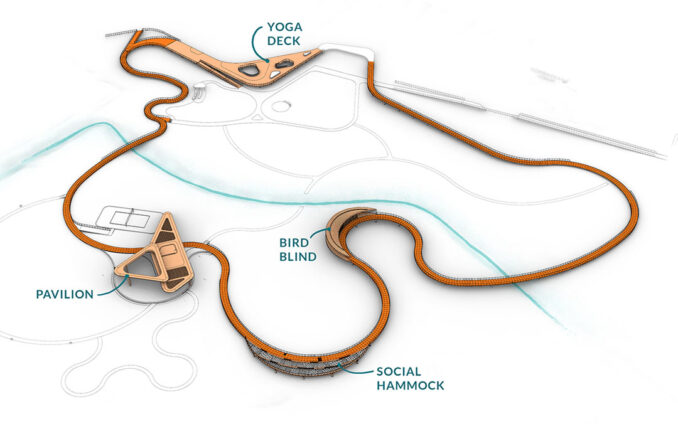

The concept for the campus was developed during the height of the COVID pandemic, spurring the client and the design team to emphasize the importance of outdoor spaces in supporting both physical and mental wellness. At its most basic, the boardwalk provides a universally accessible path safely above the floodplain. But the boardwalk also supports a much greater purpose—encouraging people to connect to a restored landscape throughout the day, and enjoy the range of physical and mental health benefits that immersion in nature provides. The boardwalk enables people to levitate above an ecologically restored landscape at varying heights depending on the surrounding topography—at times skimming the top of a meadow and at others traversing the canopy of a riparian woodland. Within the restoration area ecology is given priority, allowing flora and fauna to circulate and re-establish freely below. Meandering curves create an ever-changing sequence of vistas, connecting a variety of destinations for individual enjoyment and social engagement such as an elevated bird blind, a large cargo net hammock, an architectural pavilion, and an overlook deck adjacent to the campus core.

The boardwalk is located within the floodplain of an urban creek

Programmatic elements along the boardwalk

Concept rendering of the boardwalk and hammock

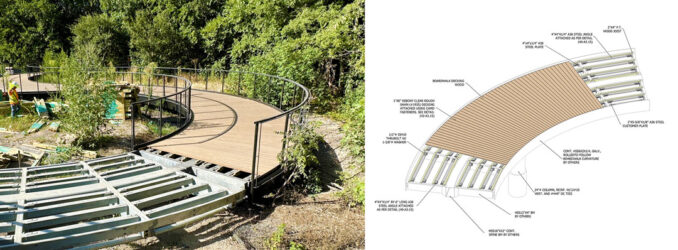

Given the location of the path, the refinement of construction details for the boardwalk required responding to a variety of very specific constraints. The path needed to be wide and robust enough to support the use of small vehicles, but also needed to minimize its physical footprint within the sensitive landscape. To prevent additional burdens on the floodplain, the structural support of the boardwalk section was designed as a single pier support along the center of the walk. The curved box beam spine of the structure supports lateral cross members cantilevering to the outer edges of the 3m wide path. Complex flood modeling was used to ensure there was no adverse impact to the flow of flood water with the addition of the boardwalk.

Boardwalk structure

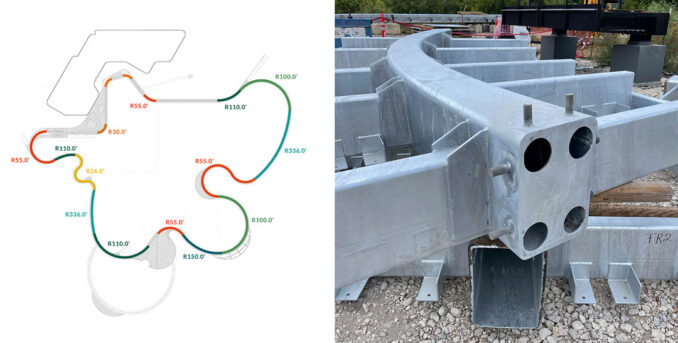

With the preservation and rehabilitation of the landscape the utmost priority, the reduction of construction impacts to the existing environment was a critical factor in design decisions. This required both a high level of precision in design and detailing, as well as clear and open communication with the contractors of the many trades involved. The boardwalk was modeled and detailed to a high level of accuracy using both 2D and 3D software throughout the project to illustrate design intent and user experience, as well as communicate constructability to the contractor. Over its 1-km length, the geometry of the path was simplified to utilize only eight different radii to streamline fabrication. The resulting layout balances efficiency of construction with a responsiveness to existing site conditions—at times threading between existing trees by only a few feet of clearance.

Standardized boardwalk radii allowed for pre-fabricated segments

The boardwalk weaves through existing vegetation

Highly-detailed shop drawings were produced and reviewed for every linear foot of structure and guardrail assembly. The majority of the heavy duty steel structure was fabricated in segments off-site and then craned and assembled in place, increasing precision and reducing construction activity within the recovering landscape. This commitment to accuracy also allowed for efficiency between trades in following stages of construction, such as the trapezoidal wood boards that could be pre-cut to fit the standardized width and radii of the path.

The prefrabrication process allowed for standardized tapered boards

In addition to meticulous planning, a thorough understanding of the limitations of construction methods, order of operations, and available equipment was critical to achieving a high-quality element with minimal environmental disturbance. Sometimes this required pushing for more than just standard construction practices, and often necessitated creative problem solving between the design team and the contractors. For example, when a company first arrived on site to drill the piers for the structure, they requested nine additional existing trees be removed to provide overhead clearance for their equipment. With the design team rejecting this proposal within an area dedicated to environmental restoration, the contractors were able to provide an alternate solution using a specialty low-headroom drilling rig, thus preserving all of the trees. While seemingly a simple outcome, it required a design team to push beyond the first solution offered, contractors willing to think outside the box in support of project goals, and—perhaps most importantly—open communication and respect between the two.

Currently Springdale Green and its boardwalk are on track for completion in early 2024.

Springdale Green Boardwalk

Project Team:

Client: Jay Paul Company

Landscape Architect: dwg.

Architect: Gensler

Civil: Kimley-Horn

Structural: IMEG

MEP: EEA Consulting Engineers

Lighting: Tillotson Design Associates

General Contractor: Level 10

Geotech: Terracon

Steel Fabrication: Patriot Erectors

Millwork: Duffin Architectural Solutions

Deck Material: Kebony

Image Credits: Renderings & photos courtesy of dwg.; Millwork shop drawing courtesy of Duffin Architectural Solutions

Text Credits: dwg.