PLYGROUND is the latest design from dgd:DGILLENdesign for TexFab’s annual digital design and fabrication competition. The competition investigated ‘Plasticity’ through an architectural proposal that utilizes parametric design and digital fabrication. Plasticity is the quality of being able to be made into different shapes, to be molded or altered. DGD saw an opportunity to create a catalyst for human interaction, envisioning an architecture where public interaction and engagement is heightened, facilitating undefined perspectives.

PLYGROUND interprets plasticity through user experience, form, and environment. As opposed to creating another ‘please do not touch’ parametric sculpture, PLYGROUND sets a new precedent in parametric design and digital fabrication by appealing to a broader user group, the next generation of designers, our youth. This fun landscape educates the public through engagement on the future of parametric design and digital fabrication. PLYGROUND exemplifies plasticity by creating a space for unscripted social experiences. By encouraging visitors to find creative ways of inhabitation, PLYGROUND succeeds in sparking curiosity and intrigue through its familiar yet foreign form.

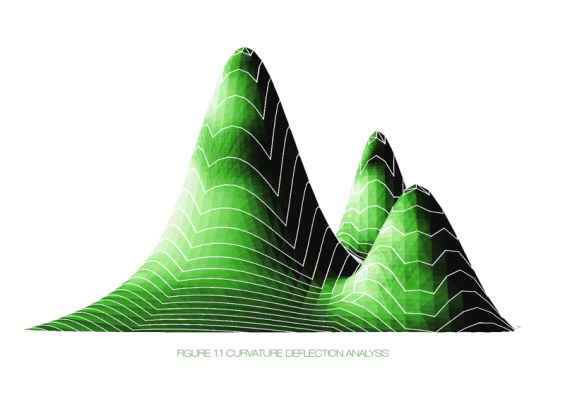

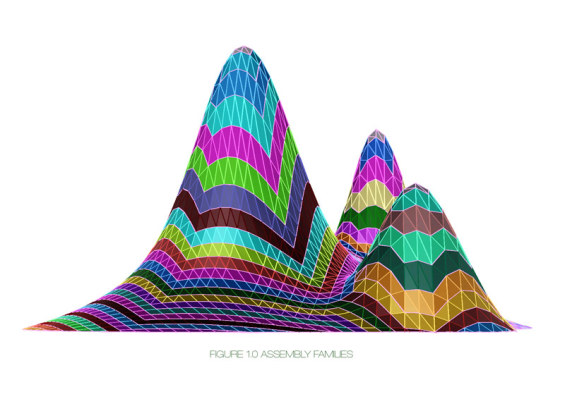

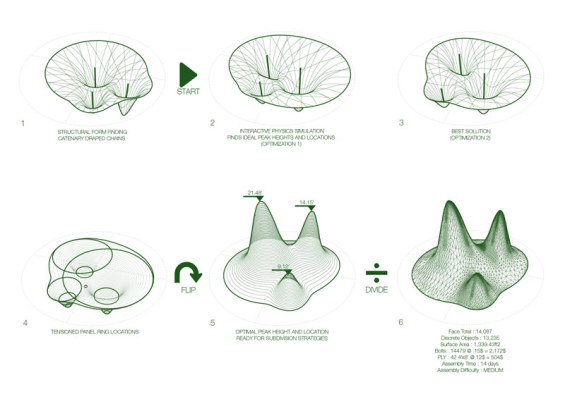

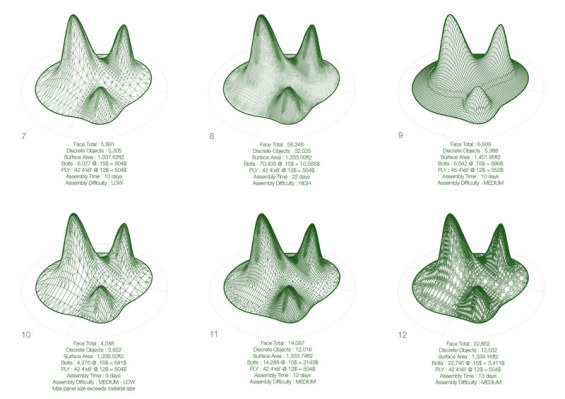

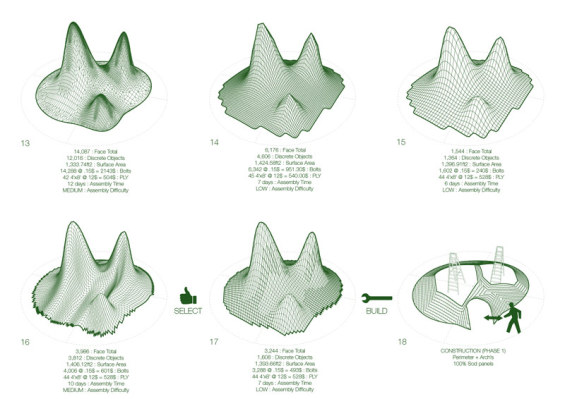

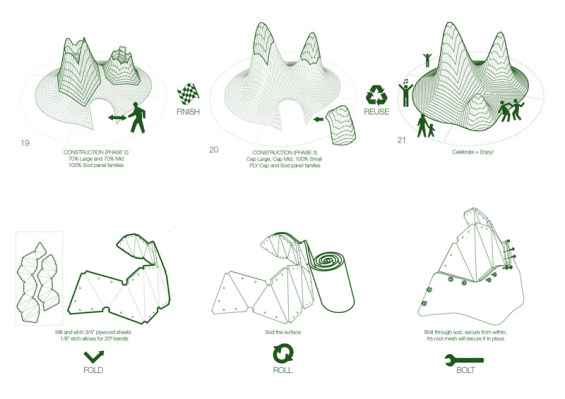

Think of PLYGROUND’s form as a three dimensional puzzle, wherein the pieces can be dismantled and reassembled in three alternate configurations with differing peak heights and locations. This flexibility in design allows PLYGROUND to adapt to different environments, spaces, and purposes. Parametrically draped catenary chains generated three peaks that optimized tectonic geometry and structural loads. Surface subdivision strategies were evaluated by fabrication and assembly time, cost, and aesthetics while plywood ‘ribbons’ were algorithmically packed to reduce material waste. PLYGROUND is designed with the DNA to transform into four unique topographies, extending the projects life through adaptive re-use.

PLYGROUND is born from, CNC milled plywood, grass sod and lag bolts. The design is a symbiosis between strictly controlled digitally fabricated components and the 100% natural. “It was a conscious decision to use renewable and biodegradable materials that could be recycled or re-used following the installation,” emphasizes designer Daniel Gillen. “We were aware that the competitions sponsor was a plastics company and it was a risk, but our idea of ‘Plasticity’ includes designing for a projects full lifecycle. ‘Plasticity’ should be addressed by designers with the responsibility of how the project begins and lives, but also how it ends.”

Design: Daniel Gillen

Visual Assistance: Philipp Ohnesorge